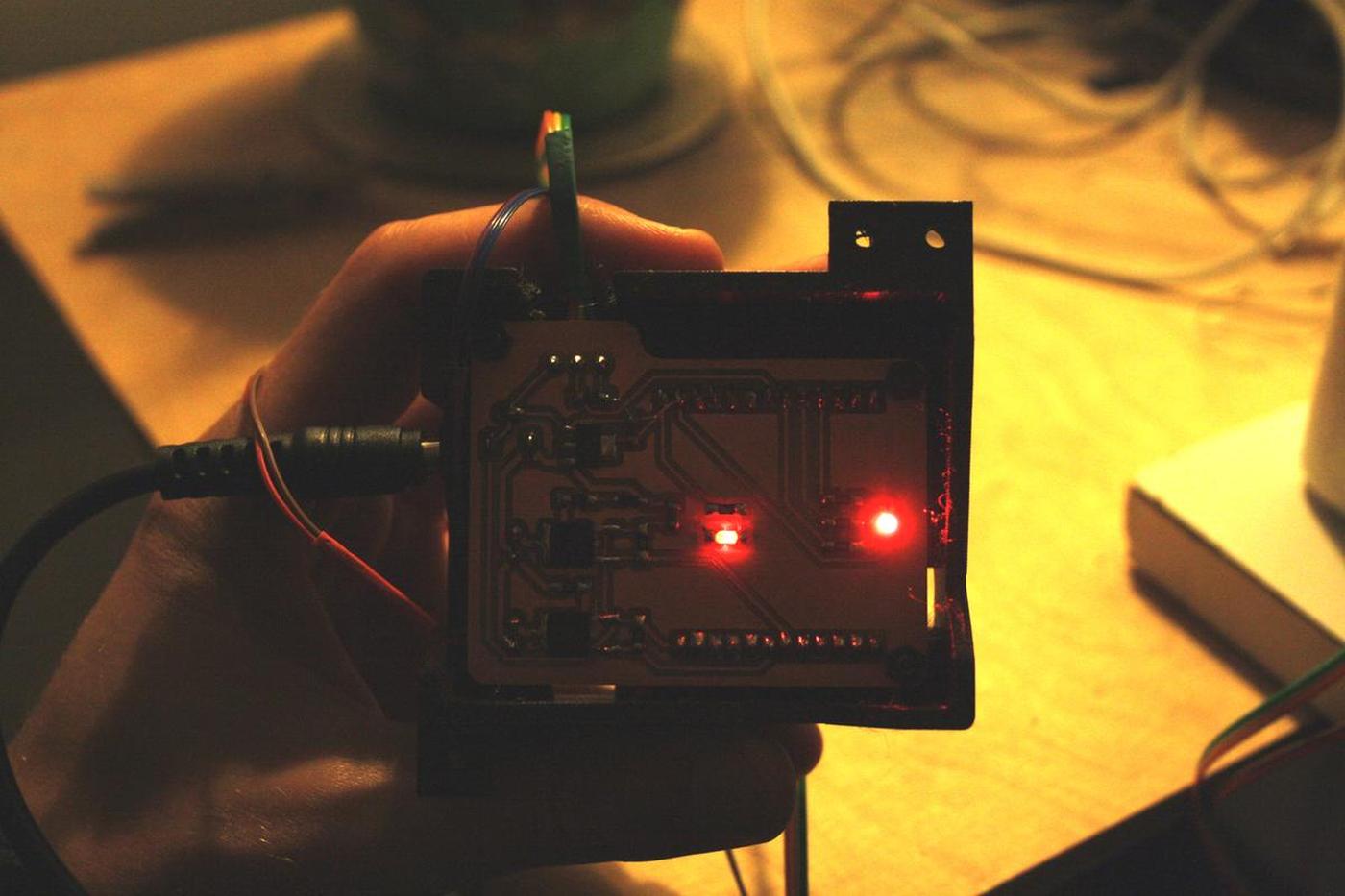

Now that the electronics is working, I need to protect it a little to avoid mishandling that could damage it. To do this, I will design a case which will then be printed in 3D.

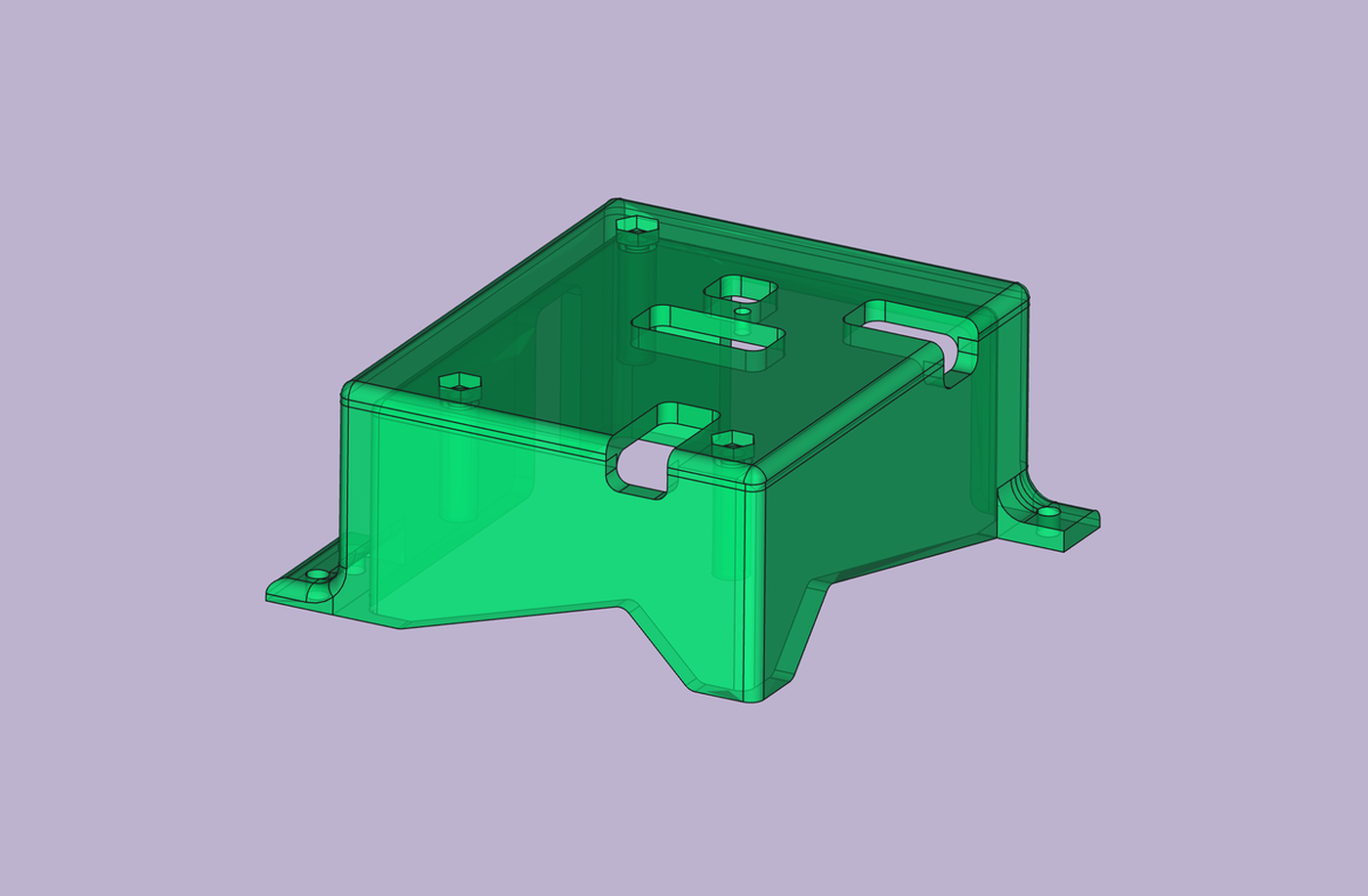

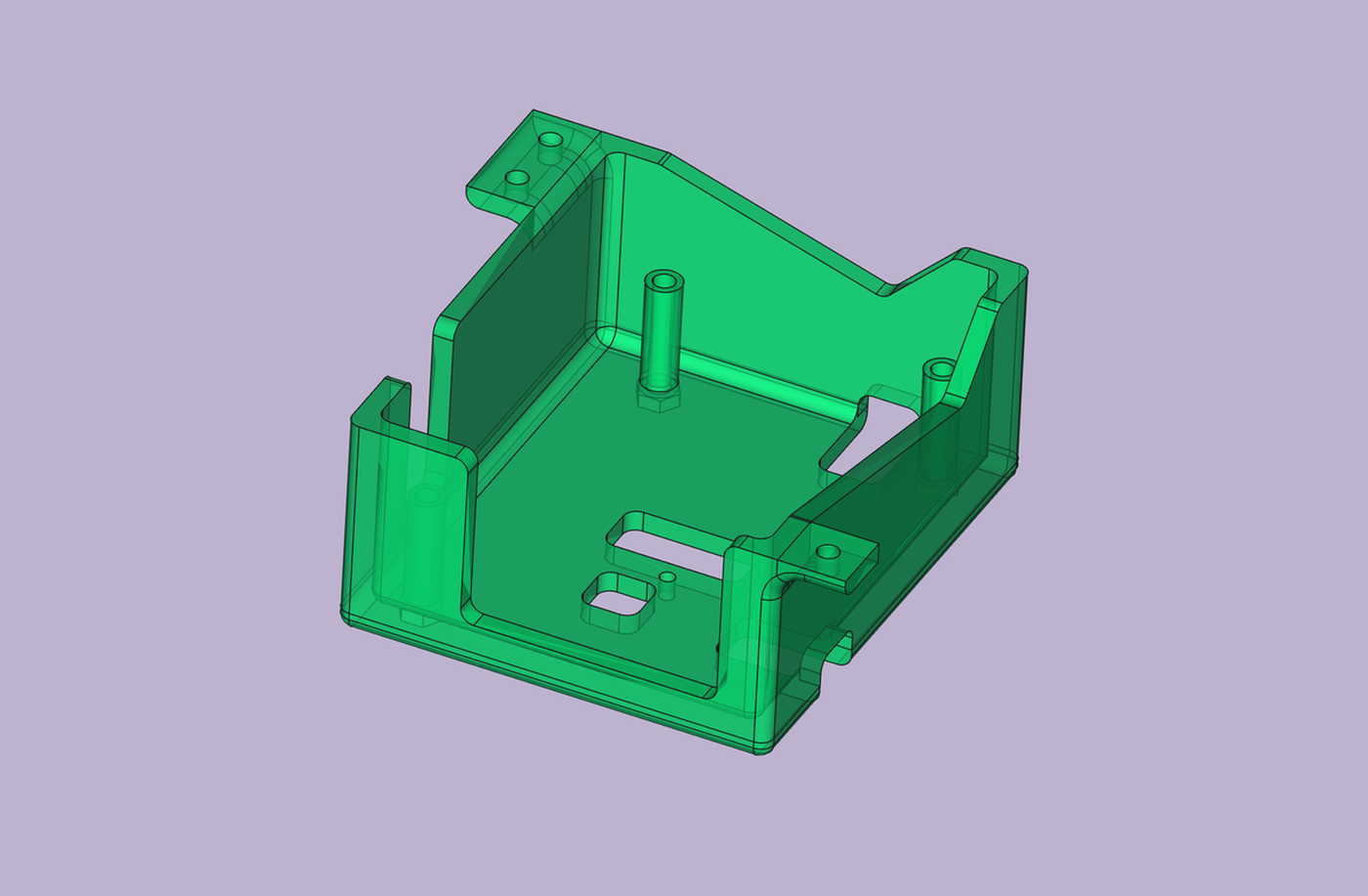

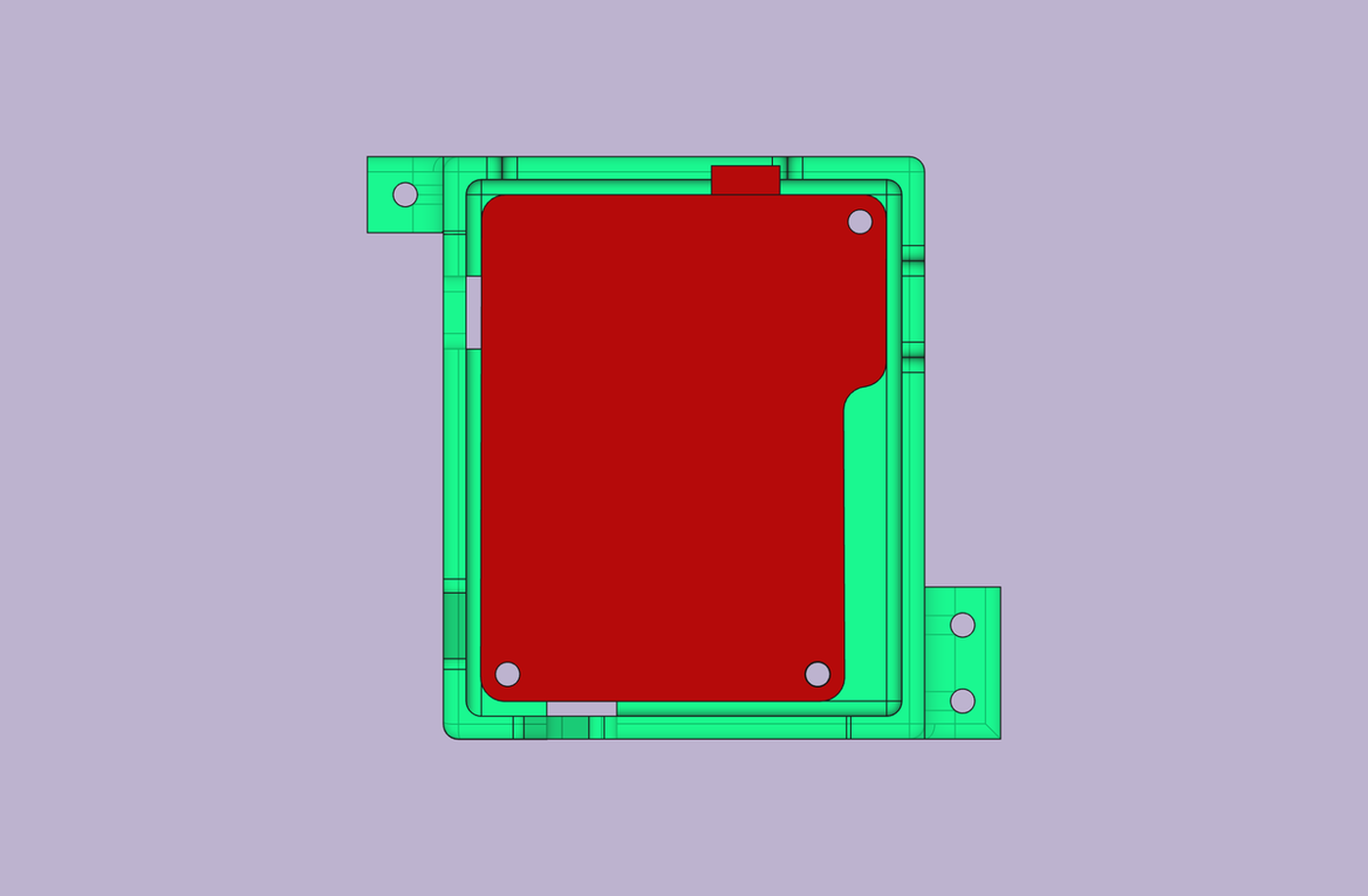

Design

The main idea of this design is to have all the functions accessible while having a light reflection that communicates the state of the incubator (if it is heating up, or if it has reached the desired temperature, or if it is cooling down).

To do: Add technical details

What must remain accessible

- the USB port

- Barrel jack

- Reset button

- Programmer switch

- Terminals (3)

- ESP32 antenna

A way to fix it

Also, we need to find a way to fix the electronics in the case and then the case in the incubator, for this I will use M3 bolts and nuts. I downloaded a 3D model of the M3 nut that I incorporated into my design.

From KiCAD to FreeCAD

Both KiCAD (Electronics design) and FreeCAD (2D and 3D parametric modeler) are open-source and work hand in hand in order to facilitate the use of one after the other. FreeCAD's KicadStepUp workbench allows to import a 3D model from a PCB designed in KiCAD to start designing from it.

Views

Fabrication

I printed this project at home using our new Mini Prusa 3D printer. I'm always amazed at the final quality of this printer. The only thing I have to adjust is the way I make my supports. They always marked my prints badly, which reduces the quality. The print was done in ~4 hours.

Result

It went so well. The reflection of the light is as I had imagined and my measurements were good! Well, almost good, because I had to cut my USB cable to fit my design.